Table of Contents

Here’s everything you need to know about stairs – whether it’s choosing a style or materials, perfecting measurements or getting the basics on installation.

Step-by-step process

1. Design consultation meeting

To start off, we’ll have a design consultation meeting with you, where we

- define the scope of the project

- establish what style you like

- problem solve any issues

- and answer any questions you have.

If you have architectural plans, we would love to see them.

2. Taking measurements

- the floor-to-floor height

- the maximum horizontal distance available from the slab to the first step where the stair lands

- the width of your treads

- slab thickness

- the thickness of tiling or carpet on both levels

- and the thickness of your treads.

3. Creating a fabrication drawing

4. Design approval

5. Making your stairs

Choosing your stairs

- When deciding what stairs best suit your needs, there are a few key decisions to make. These include:

- what materials your stairs will be made from

- what kind of layout suits your space

- the profile of your staircase

- and what material your treads will be made from.

Types of stair layouts

First you must choose the materials you want the structure of your stairs to be made from, and this should be guided by both aesthetic and practical considerations (such as will your stairs be inside or outside). Your options include:

- mild steel (a long-lasting, low-carbon steel designed for manufacturing) that can either be painted or galvanised

- stainless steel

- timber – such as Jarrah, Taji Oak, Malaysian Cherry and more

- or MDF

Types of stair materials

Straight stairs

Stairs can come in a number of different layouts to suit your project.

L-shaped stairs

U-shaped stairs

Floating stairs

Ladders

Stair profiles

Twin stringer stairs

Single stringer stairs

As the name suggests, they have just one stringer. Single stringer stairs look great in modern and mid-century homes, allowing minimal obstruction of light and your view.

Spiral stairs

These stairs spiral around a central support. They take up very little space but can be difficult to get up and down. They look good in both modern and traditional homes.

Open rise stairs

With this style of stairs, the vertical gap between stairs isn’t filled in with timber or other building materials, but left open. Open rise stairs let through light and don’t block your view, whereas closed risers can accommodate built-in storage but block light.

Winder stairs

Winder at one end of the tread than the other, winders wind around a central point to change the direction of a staircase without using a landing. They are ideal for a tight space.

Types of stair treads

Timber treads

Timber treads come in your choice of various timbers, such as Jarrah, Tasmanian Oak, Malaysian Cherry and more.

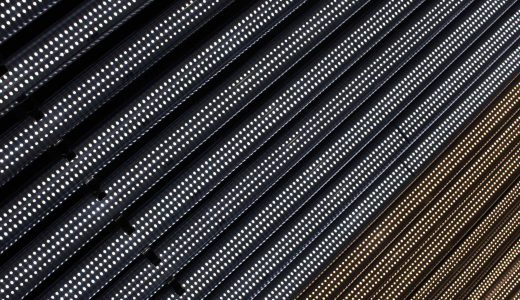

Perforated treads

Perforated steps are steel treads with a consistent ‘dot pattern’ of small holes that creates a slip-resistant surface. They allow airflow and some light to get through.

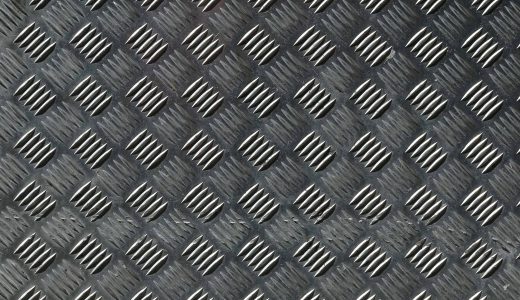

Checker plate treads

Check plate treads have a regular stamped pattern for increased slip resistance. They are perfect for industrial settings, or they can look fantastic in modern homes. Work well for external and internal stairs.

Safety standards

Generally, staircases must comply with the Building Code of Australia.

There are some cases not covered by the codes, such as stairs to non-habitable

rooms like attics, but they must still comply with Australian Standards. We’ve put

together this comprehensive guide to help, but it is essential that anyone

measuring up or installing your stairs ensures they comply with the Building Code.

Residential stairs must comply with the following;

- in each flight, all treads and risers (the height between the top of consecutive

treads) must be a consistent size (no greater than +/-5mm in variance) - stairways must be at least 600mm wide from the inside edges of the handrails

- the pitch angle must be between 26.5ºand 45 degreesº

- goings (the distance from the edge of the nosing to the edge of nosing on consecutive risers when measured from the side) must also be a consistent size (no greater than 10mm in variance)

- there must be a 750mm2 landing area every 18 risers

- a single flight must not have less than two risers or more than 18

- after 36 rises in consecutive flights, there must be a change of direction

- if the drop from the stairs to the level below is over one metre, there must also be a balustrade; the balustrade height, against the pitch of the staircase, must be at least 865mm from the nosing line and on a landing, balcony, etc, it must me above one metre

- in open rise stairs, the gap between stairs cannot allow a 125mm sphere to pass through

• and head clearance should be at least 2000mm vertically above the nosing line (the protruding edge of the step over the riser).

Dimensions for a private staircase

| Riser | Going | Quantity (2 x risers + going) |

|---|---|---|

| 115mm – 190mm | 240mm – 355mm | 550mm – 700mm |

Public properties must comply with extra regulations:

- stairs treads must be covered in a slip-resistant coating or have a non-slip strip at the front edge

- for a required stairway, you cannot use winders instead of a landing

- The width of stairway is over 1000mm, there must be a handrail on each side of the staircase

- treads must be solid (not of perforated materials) if the staircase is over 10m high or connects more than three storeys

- the going should be less than the tread depth plus up to 30mm.

- a continuous smooth handrail is required for the length of the stairs, with no obstructions that will break a handhold and have minimum 50 mm hand clearance.

Dimensions for a public staircase

| Riser | Going | Quantity (2 x risers + going) |

|---|---|---|

| 115mm – 190mm | 250mm – 355mm | 550mm – 700mm |

Maintaining your stairs

- polish timber treads if required

- regularly clean stainless steel parts to increase their lifespan, especially in coastal areas

- clean powder-coated steel or painted steel with a soft brush and a mild detergent in warm water (do not use solvents)

- and periodically visually inspect all nuts and bolts.

Please be aware all the information on this page is provided as an introductory guide. If you design,

fabricate, measure or install your own project, Aussie Balustrading & Stairs takes no responsibility.

Helpful Articles and Blogs

5 Great Reasons to Install Stainless Steel Wire Balustrades

A stainless steel wire balustrade is a type of railing system that is used to provide a barrier between two areas. It is typically made up of metal wires that are strung together in a grid-like pattern and suspended between two posts or columns. The wires are usually stainless steel, which is known for its strength, durability, and corrosion resistance, making it an ideal material for use in balustrades.

Three Impressive Benefits of Having Stainless Steel Handrail

Adding a stainless steel handrail to your home is an excellent way to add style and safety to your space. These railings are not only stylish, but they are also highly durable, making them an ideal choice for homes with children or pets. Additionally, they are easy to clean and maintain so that you can enjoy their beauty for years.

Top 9 Tips to Help You Avoid Rust on Your Steel Balustrades

As any homeowner knows, rust is the enemy of steel. Balustrades are no exception – if left untreated, rust can quickly ruin the look of your otherwise beautiful home. But don’t despair – there are a few simple steps you can take to prevent rust from taking hold of your balustrades.

Why You Should Choose Our Stairs?

Locally Made

Like all our work, our stairs are made right here in Perth, Western Australia.

Beautifully Crafted

With years of experience, our team strives for perfection with each and every job, and they make sure they always maintain the highest standards.

Fully Compliant

All our projects fully comply with all Australian standards and Building Code of Australia (BCA) requirements.

Complete Solution

We offer the complete solution, from measuring up your project, right through to installation, and we do it to the highest possible standards.